75KW BLT variable frequency air compressor

The VFC technology of BLT PM+&VFC (11-90KW) permanent magnet variable frequency series air compressors can track the changes in air demand and automatically adjust the motor speed. The average energy-saving effect can reach 30% or even more, reducing the average life cycle cost of the entire com

75KW BLT variable frequency air compressor

Details

The VFC technology of BLT PM+&VFC (11-90KW) permanent magnet variable frequency series air compressors can track the changes in air demand and automatically adjust the motor speed. The average energy-saving effect can reach 30% or even more, reducing the average life cycle cost of the entire compressor by 26%. Compared to fixed speed compressors, the additional investment cost of Bolaite variable frequency air compressors can be recovered within 1 to 2 years.

parameter

Model: BLT-100A PM+

Exhaust pressure (Mpa): 0.7/0.8/1

Exhaust volume (m) ³/ Min): 2.5-13.1/2.4-12.8/2.3-11.1

Power (KW): 75

Noise (dB (A)): 72 ± 2

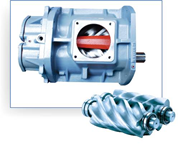

High-quality core components

Screw host is like the heart of screw compressor. Its performance directly affects the energy efficiency and service life of the whole machine.

Brett adopts Atlas Copco host, the leader in the field of air compressor.

SAP profile, optimized screw compression efficiency is more than 5% more energy-efficient than similar products in the market.

High processing accuracy, low host vibration, and low noise.

SKF heavy-duty bearings and high stiffness rotors ensure long-lasting and reliable operation.

Intelligent control system

LCD displays in both Chinese and English, with a user-friendly and intuitive interface, allowing for quick and convenient adjustment of unit

parameters.

Powerful all-round protection function: prevent faults caused by short circuits, locked rotor, phase loss, overload, etc.

Multiple signal outputs: switch analog/RS-485 port, optional large screen touch main controller.

Electrical system

With standardized design, safe and reliable Specialized wiring interface, making the wiring reasonable, compact, clear and easy for maintenance

Siemens high-configuration series components adopted to ensure safe operation for a long time

Modular design

The model with a power of ≤ 37kW adopts innovative modular design, integrating efficient main engine, valve group, main pipeline, and oil and

gas separation system, without leakage, low pressure loss, and making maintenance easier. Innovative technology has created units with high

allowable efficiency and reliability.

High quality motor

Efficient design and SKF bearings ensure the motor's ultra long lifespan.

IP54 protection fully enclosed motor can operate worry free even under harsh working conditions.

Standard phase sequence protection to prevent reversal.

Efficient and powerful cooling design

Super large oil cooler design: Even in high temperature and dusty environments, it can keep the lubricating oil temperature within the normal range,

ensuring the compressor can safely survive the summer.

Pre-filtration protection

Unique pre-filtration screen cover, which can keep the interior of the whole machine clean and prolong the maintenance period, is easy to remove,

install and clean, and is reusable